Garments & Textile Factory in Bangladesh

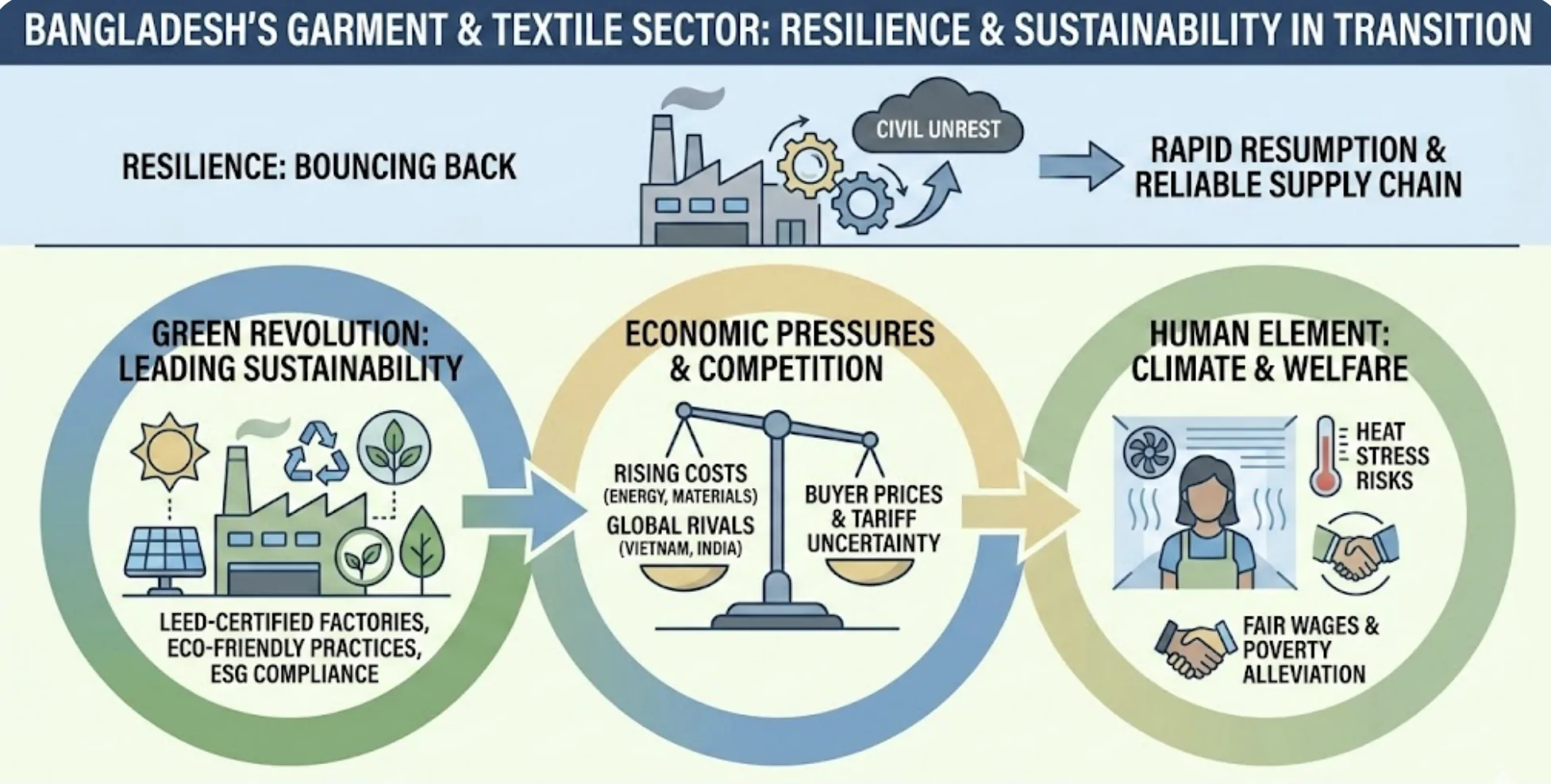

The textile and garment industry is the lifeblood of Bangladesh. As the world’s second-largest apparel exporter, the “Made in Bangladesh” tag is found in wardrobes across the globe. However, the industry is currently navigating a complex landscape of political change, environmental demands, and intense global competition.

In this article, we explore the current state of Bangladesh’s textile factories, the shift toward sustainability, and the challenges workers face on the ground.

Story of Resilience: Resuming Operations

Recent civil unrest in Bangladesh created significant disruptions across the manufacturing sector. However, the industry has shown remarkable resilience. Factories have swiftly resumed operations to ensure global supply chains remain intact. This ability to bounce back reinforces Bangladesh’s position as a reliable partner for global fashion brands, even in times of domestic volatility.

Green Revolution: Leading the World in Sustainability

One of the most significant shifts in the Bangladeshi garment sector is the move toward “Green Factories”. Driven by buyer demand and a national commitment to the environment, Bangladesh now boasts some of the highest numbers of LEED-certified factories in the world.

- Why Go Green? International buyers are increasingly demanding transparency and carbon footprint reduction.

- The Impact: Sustainable factories focus on water recycling, energy efficiency, and waste reduction, making them more attractive to high-end global brands looking to meet ESG (Environmental, Social, and Governance) goals.

Economic Pressures and Global Competition

Despite its dominance, Bangladesh faces a “squeeze” from several directions:

- Rising Rivals: Countries like Vietnam and India are aggressively competing for market share. While Bangladesh benefits from low labor costs, rivals are often seen as having faster logistics or more favorable trade agreements.

- Tariff Challenge: While some US tariff cuts have assisted the industry, experts fear that shifting geopolitical alliances and trade policies could impact long-term growth.

- Cost vs. Price: Factories are facing rising costs for raw materials and energy, while global buyers are often hesitant to increase the prices they pay per garment.

Human Element: Climate Change and Worker Welfare

The industry employs over 4 million people, a majority of whom are women. However, the “human cost” of production is becoming a central topic of discussion.

- Heat Stress: As global temperatures soar, garment workers are falling ill due to extreme heat inside factories. This has led to calls for better ventilation, hydration breaks, and climate-adaptive factory designs.

- Poverty Alleviation: The industry remains the primary vehicle for poverty reduction in Bangladesh, providing millions with a path to financial independence, yet the struggle for fair living wages continues.

Quick Facts: The Industry at a Glance

- GDP Contribution: The textile industry accounts for roughly 80% of Bangladesh’s total export earnings.

- Global Rank: 2nd largest exporter of RMG (Ready-Made Garments) after China.

- Certification: Home to the world’s highest number of eco-friendly garment factories.

CONTACT US

- MESSAGE US ON FACEBOOK: https://www.facebook.com/rbsublimationsignage

- CALL/TEXT: +639460480491