Textile Factory 7.0 in Germany

The global textile industry is at a crossroads. As the demand for sustainability, transparency, and localized production grows, traditional manufacturing models are being challenged. Enter Textile Factory 7.0 (T7) – a pioneering project launched in Mönchengladbach, Germany, aimed at redefining the next industrial era.

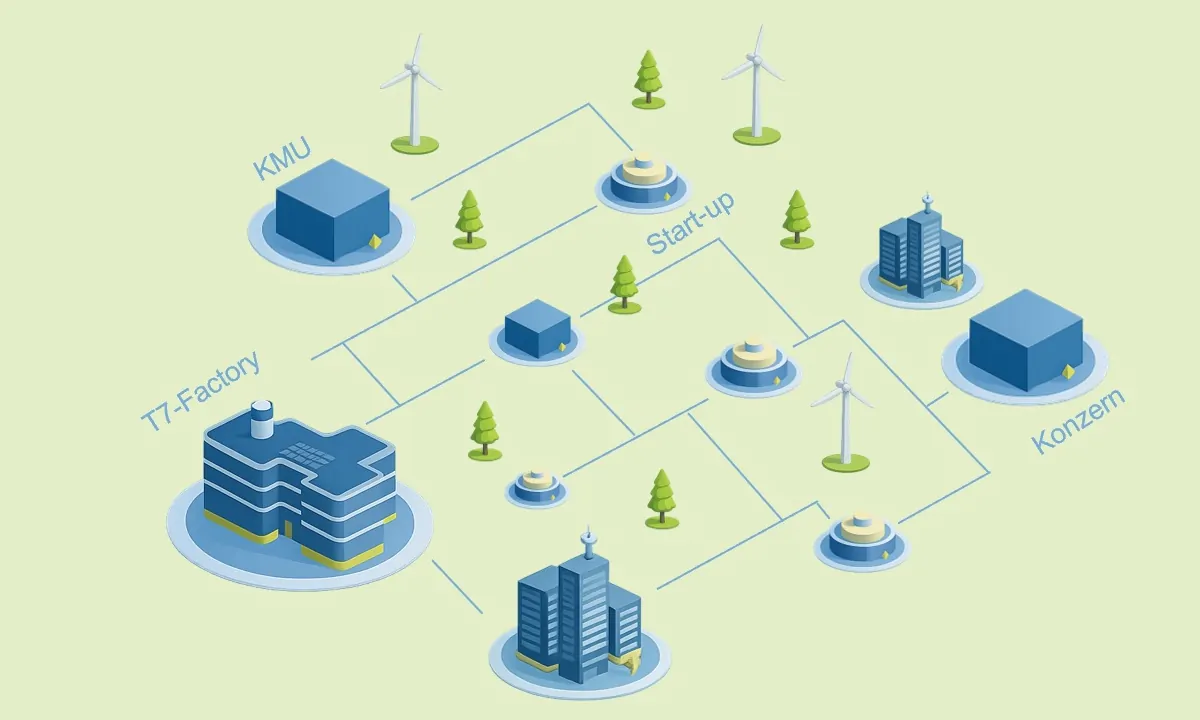

Developed by the Niederrhein University of Applied Sciences in collaboration with various industrial partners, Textile Factory 7.0 is more than just a smart factory; it is a “real-world laboratory” designed to integrate cutting-edge technology with ecological responsibility.

What is Textile Factory 7.0?

While “Industry 4.0” focused on the digitalization of manufacturing, Textile Factory 7.0 pushes the boundaries further. It represents a holistic ecosystem where AI, robotics, biotechnology, and the circular economy converge.

The project, which recently received significant backing and awards from the state government of North Rhine-Westphalia (NRW), aims to solve the “magic triangle” of textile production: achieving high quality and sustainability while remaining economically competitive in high-wage regions like Europe.

Key Pillars of the T7 Model

AI-Powered Precision

Artificial Intelligence is the brain of the T7 factory. AI is used to optimize every stage of production, from predictive maintenance of machinery to automated quality control. By utilizing AI-driven sorting and processing, the factory can significantly reduce waste and ensure that resources are used with maximum efficiency.

Robotics and Automation

To make local production viable in Europe, T7 leverages advanced robotics. These systems are designed to handle flexible materials – traditionally a difficult task for robots – enabling the automation of complex sewing and assembly processes. This reduces the reliance on long, carbon-intensive global supply chains.

Biotechnology and Innovative Materials

One of the most distinct features of Textile Factory 7.0 is its focus on biotechnology. The project explores the use of bio-based fibers and environmentally friendly finishing processes. By integrating biological cycles into industrial production, T7 aims to create textiles that are not only durable but also fully biodegradable or recyclable.

Circular Economy and Sustainability

Sustainability is the heartbeat of the project. T7 is designed to be energy-efficient and focused on a “closed-loop” system. This aligns with the recent upgrades in global standards, such as GOTS 7.0, which demand stricter ecological and social criteria. The factory serves as a model for how the industry can transition from a “take-make-waste” model to a truly circular one.

Why Mönchengladbach?

Mönchengladbach has a deep historical connection to the textile industry, often referred to as the “Manchester of the Rhine.” By hosting the Textile Factory 7.0 project, the city is positioning itself as a global hub for textile innovation. The Niederrhein University of Applied Sciences, a leader in textile technology, provides the academic and research foundation necessary to bridge the gap between laboratory concepts and industrial application.

The Significance of the “7.0” Designation

In the garment industry, the number “7.0” also appears in specialized contexts like the 7.0 System in Garment Inspection. This quality control system is used to evaluate fabric and garment defects with high precision. By adopting the “7.0” nomenclature for the factory of the future, the project signals a commitment to the highest possible standards of quality, inspection, and technological integration.

Contact Us

- Call or text me at 09460480491

- Message us on Facebook at https://www.facebook.com/rbsublimationsignage/