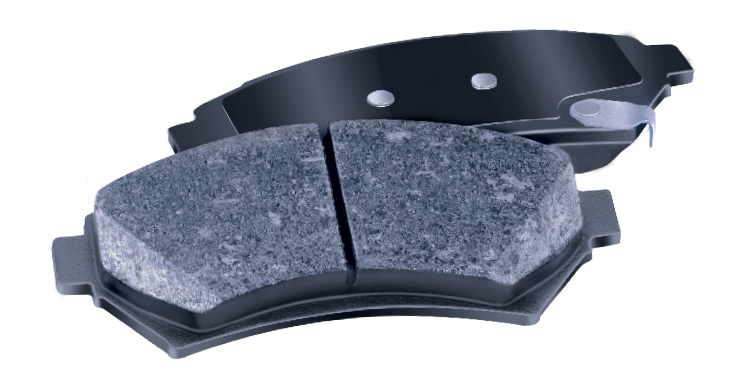

A brake pad is a crucial component of a disc brake system used in vehicles, such as cars, motorcycles, and bicycles, to facilitate the process of slowing down or stopping the vehicle.

Here are some key points about brake pads:

- Function: Brake pads are designed to create friction against the rotating brake rotor, resulting in the conversion of kinetic energy into heat energy. This frictional force helps to slow down or stop the vehicle by reducing the rotational speed of the brake rotor.

- Composition: Brake pads are typically composed of friction material bonded to a metal backing plate. The friction material is often made from various formulations, such as organic materials, semi-metallic compounds, or ceramic materials. Each formulation offers specific performance characteristics in terms of friction, heat resistance, wear resistance, and noise reduction.

- Types of Brake Pads:

- Organic Brake Pads: Organic brake pads are made from a mixture of organic materials, such as rubber, glass, and Kevlar fibers. They provide good initial bite, low noise levels, and are typically gentle on the brake rotors. However, they may have lower heat resistance and can wear faster under heavy braking.

- Semi-Metallic Brake Pads: Semi-metallic brake pads contain a blend of metal fibers, such as steel or copper, along with other materials. They offer improved heat dissipation, durability, and braking performance. However, they may generate more noise and have a slightly harsher feel during braking.

- Ceramic Brake Pads: Ceramic brake pads are composed of ceramic fibers, bonding agents, and other fillers. They provide excellent braking performance, low noise levels, minimal dust generation, and reduced wear on both the brake pads and rotors. Ceramic pads are often considered a high-performance option, but they may be more expensive than other types.

- Wear and Replacement: Brake pads gradually wear down over time due to the frictional forces involved in braking. The rate of wear depends on factors such as driving style, vehicle weight, and the type of brake pad material. It is crucial to monitor the thickness of the brake pads regularly and replace them when they reach their minimum allowable thickness to ensure optimal braking performance and safety.

- Maintenance and Inspection: Regular maintenance includes inspecting the brake pads for signs of wear, uneven wear patterns, or any damage. It is essential to keep the brake pads clean and free from contaminants that can negatively impact braking performance.

Properly functioning brake pads are essential for safe and effective braking. It is important to follow manufacturer recommendations regarding brake pad selection, maintenance, and replacement intervals for optimal braking performance and safety.

IMAGE GALLERY

CONTACT US

For details, do any of the following:

- Call or text me at 09460480491

- Message us on Facebook at https://www.facebook.com/rbsublimationsignage/